Open mon-fri

7.00 - 16.00

RIIKO® Timber Superstructures

Sales with practical experience

Our new Sales Manager, Antti Pikkarainen, has already implemented numerous customer projects during the spring. His practical approach has been approved, and new solutions are constantly being developed together with customers. Pikkarainen is familiar with heavy equipment both in the workshop and behind the wheel. Before moving into sales, he worked as a foreman in the assembly of RIIKO® Superstructures, and before that, he gained over ten years of experience as a driver of timber, hook lift and gravel trucks. This background gives him a practical perspective of what customers really need – and how to create smart solutions from the start. Pikkarainen is happy to help with any questions – whether it is new equipment, used machines or financing solutions. +358504718404 and antti.pikkarainen@riiko.fi

RIIKO® Superstructure is a Key Flag product

RIIKO® is our own brand, whose main products are superstructures for trucks and trailers. RIIKO® Superstructures have been designed, manufactured and assembled in the city of Joensuu, Finland, for over 30 years. We are the only operator in our field that manufactures all superstructures in our own production chain. The Association for Finnish Work has awarded the Key Flag symbol to RIIKO® Superstructures, which serves as a strong indication of Finnish work. We thank all our customers for decades of trust in our products and work!

You choose - we implement

RIIKO® timber superstructures are made brand-free for all trucks according to the special requirements of all axle and suspension options. Our crane brackets are also implemented for all crane models. Crane assembly is dimensioned according to the selected chassis type and the loads to be driven on it, without forgetting the effects of the crane's center of gravity on the truck's driving characteristics in different situations. For the RIIKO® subframe package, you can choose the components and dimensions according to your needs, so that the finished whole is exactly what you need. We produce lots fo unique solutions from special crane brackets to small accessories according to our customers wishes.

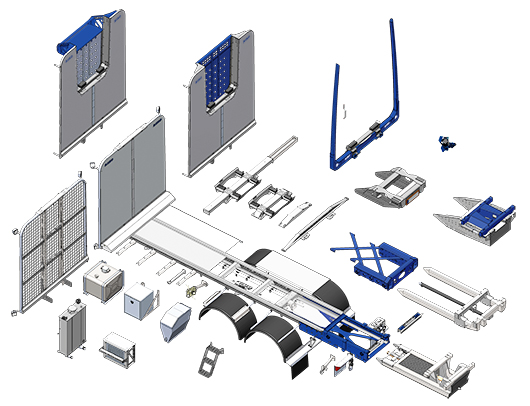

RIIKO® optimizes load capacity

RIIKO® timber superstructures made of modern special steel guarantee maximum payload for your timber truck. RIIKO® timber superstructure is both light and durable. The modular structure makes the RIIKO® superstructure a safe choice. The components of the superstructures are put together with bolted joints, which guarantees easy maintenance and modification of the truck. In addition to production, we offer comprehensive maintenance and spare parts services so that your equipment can be maintained carefree in the future as well.

RIIKO® Timber Bunks

RIIKO® 8T is the markets lightest timber bunk with detachable stakes. The material used in RIIKO® Timber Bunks is high strenght steel which is treated with steel shot blasting and painted with zinc primer. Bunks are painted with 2-layer powder coating according to RAL colors. Also available galvanized timber bunks. RIIKO® 8 ton bunks have detachable stakes, and the bunks are available with various fixing options. Height options 2500 mm-3250 mm. We deliver RIIKO® Timber Bunks quickly and with affordable freight!

Own production chain guarantees fast delivery

The entire production chain of our superstructures, from design to assembly, takes place in the same yard, which means that your order is completed on schedule. All RIIKO® products are made by us, beginning from the press brake bending and ending to the surface finishing. We also handle inspections in the inspection station next to our workshop. Our competent staff ensures that the superstructure is professionally executed down to the last detail and that the equipment leaving our workshop certainly meets your requirements.

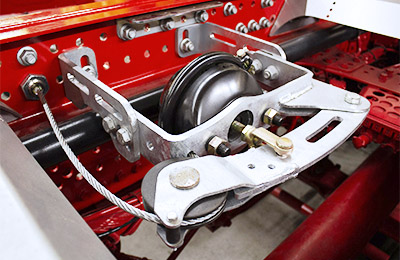

RIIKO® pneumatic tightener for timber trucks

The RIIKO® pneumatic load tightener produces a continuous tightening force of 5.4 kN and is available with chain or cable. The binding remains as tight as required, even if the load changes its shape slightly during driving. The RIIKO® load tightener is mounted on the inside of the subframe of the truck or trailer with a bolt attachment. The installation can be carried out by a driver himself, operation requires only pneumatic supply. From us you can get a ready-to-install load tightener package easily delivered.

Retail and representative

From us, you can get all heavy equipment products for timber trucking easily in one place. In addition to our own production, we operate as an official dealer for Tamtron crane scales and Kilafors trailers. In addition, you can also get tires and rims for heavy machinery and spare parts from a comprehensive selection. You get everything you need as a total delivery, from order to inspection.

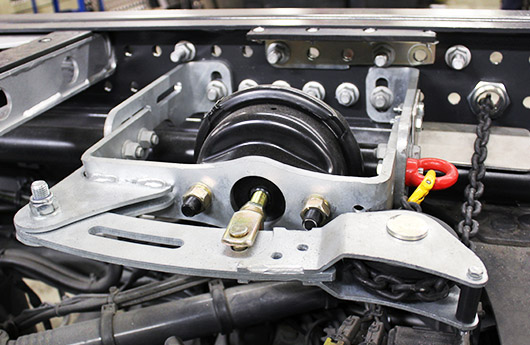

RIIKO® equipment options

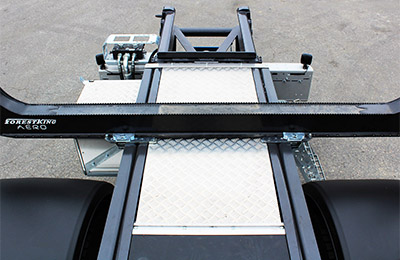

RIIKO® Subframe Kit

You can choose from the various components the options and dimensions that best suit your needs. In timber superstructures, the equipment options mainly consist of our own RIIKO® products, the main material of which is high-strength steel. All steel parts to be painted on the superstructure are treated with steel ball blasting, painted with zinc primer and surface-treated with paints according to RAL colors. In addition, equipment options include a wide range of reliable and tested components from our subcontractors, such as hydraulics, sanding equipment, coupling equipment, lights and timber bunks.

Subframe

As material 6mm high-strength steel. The subframe profiles are assembled using steel cross-members and bolted joints only. The non-welded structure guarantees a long service life for the subframe.

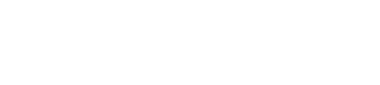

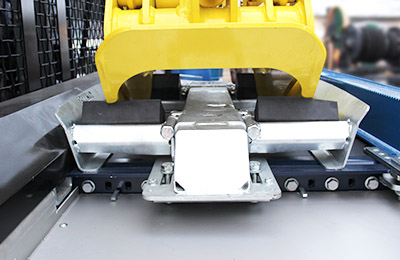

Sockets of internal crane bracket

The cross-reinforced structure of the detachable crane bracket sockets increases torsional rigidity, improving operating comfort when driving and using a crane. The crane is easy to remove and reattach, allowing the crane to be removed during transport to maximize payload.

Internal crane bracket

The internal detachable crane bracket is made to order according to the brand and model of the crane. The crane bracket is equipped with a long-stroke hydraulic cylinder with an operating distance of 1850mm. The crane can be moved to the rear up to 1000mm, making it easier to load the truck and trailer.

Fixed crane bracket

Kiinteän rakenteensa ansiosta nosturiteline on erittäin vakaa lastauksen aikana ja paras vaihtoehto, kun nosturin irroitustarvetta ei ole.

Fixed detachable crane bracket

Combination of fixed and detachable crane bracket. Crane can be moved to maximize the payload.

Sockets of external crane bracket

The sockets of traditional external detachable crane bracket are made to order according to the brand and model of the crane. The crane bracket can be removed during transport to maximize the payload.

External crane bracket

The traditional external detachable crane bracket is made to order according to the brand and model of the crane. The crane bracket can be removed during transport to maximize the payload.

Sockets rear tightener

The rear hydraulic tightener of the detachable crane bracket sockets eliminates the clearance by wedging the socket structure rigidly, thus reducing oscillation during loading.

Sockets front tightener

The front tightener of the detachable crane bracket sockets eliminates the clearance and together with the rer tightener produces steady douple tightening for the internal crane bracket.

Transfer cylinder locking device

Detachable crane brackets transfer cylinder locking device is available both mechanical and pneumatic. The locking device keeps the crane bracket securely locked during crane operation and transport.

Hydraulics

1-circuit, 2-circuit and LS hydraulics available. Our subcontractors are Hawe, Parker, Leduc and Rexroth as pump options. Steel valve cover.

Timber Bunks

Available RIIKO® 8T timber bunks with detachable stakes and all the other bunk brands on the market.

Headboard with grapple rack

Headboard with grapple rack and aluminium sheet. Headboard is available with openings for lights and through-flow holes to reduce air resistance. Height selectable.

Painted headboard with grapple rack

Painted headboard with grapple rack and aluminium sheet is also available painted according to RAL colours, either completely or just the steel frame. Height selectable.

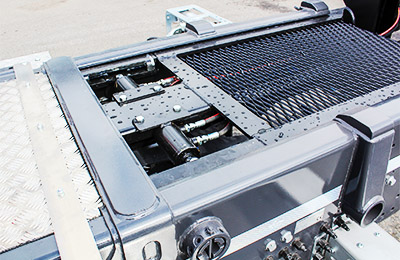

Headboard with steel wire net

Headboard with grapple rack and steel wire net. Net and grapple rack available painted in RAL colours. Height selectable.

Straight headboard

Straight headboard with aluminium sheet. Headboard is available with openings for lights or window and through-flow holes to reduce air resistance. Available painted according to RAL colours. Height selectable.

Staright headboard with steel wire net

Straight headboard with steel wire net. Available painted in RAL colours. The thinnest headboard model, depth only 165 mm. Height selectable.

Straight headboard with visor

Straight headboard with aluminium sheet and visor. Headboard is available with openings for lights and through-flow holes to reduce air resistance. Available painted according to RAL colours. Height selectable.

Staright headboard with net and visor

Straight headboard with steel wire net and visor. Available painted in RAL colours. Height selectable.

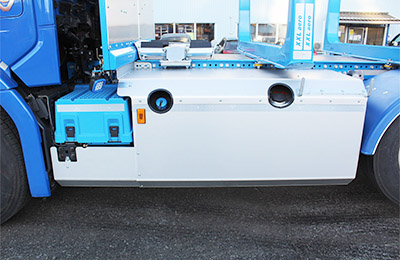

Headboard oil tanks

Headboard oil tank assembled between cabin and the headboard. The headboard oil tank saves space from the subframe for other equipment and is compatible with all headboard models.

Frame oil tanks

As an option for headboard oil tank our subcontractor´s Kovi oil tank assembled to the side of the subframe.

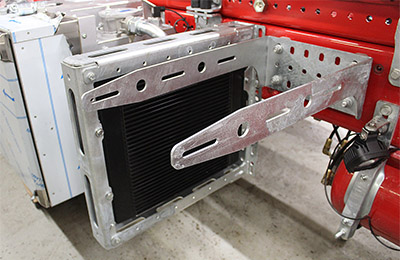

Oil coolers

The oil cooler prevents the crane's hydraulic oil from overheating during heavy-duty operation. As coolers, we use Hydac brand. The bracket is mounted on the subframe and for example step boards can be connected to the assembly.

Cooler-sanding gear bracket

Oil cooler bracket compatible for sanding gear . Changing the sanding gear and oil cooler along usage which leaves space from the subframe for other equipment.

Sanding Gear

The heat resistance controlled from the cabin of aluminium-framed sanding gears prevents the sand and feed rollers from freezing. Can be mounted directly on the subframe or on a support bracket to the subframe. Brands Rempsu and IceFighter.

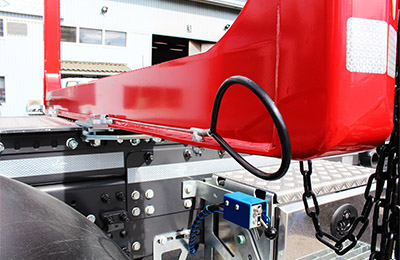

Pneumatic load tightener

Pneumatic load tightener, where the binding is automatically tightened during transport. The attachment on the inside of the subframe from which the hooked tensioner wire is brought to tank cover or bunk.

Load binding chain brackets

Load binding chain brackets effectively prevent chain entanglement. In our model, an additional fastening at the bottom of the bracket.

Load quick release

The quick-release devices have several model options that can be attached to a timber bunk or subframe.

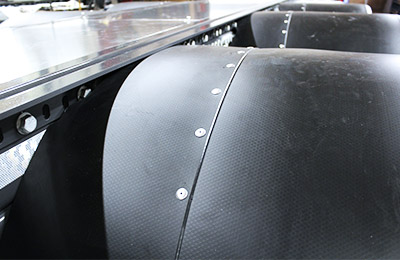

Frame decks

Thanks to the frame decks, the platform remains protected from hits, dirt, water and snow. Removable frame decks are made of plastic, plywood or hardened aluminium.

Tank shields

The tank shields effectively protect the tanks from falling trees during loading and unloading, for example. A side underrun protection plate can be connected to the tank cover.

Walking decks

The walking deck at the front of the crane bracket is made of hardened aluminium, which is sturdy and durable in all conditions.

Timber bunk transfer

Hydraulic transfer system for first and fourth timber bunk.

Load divider

Weight transfer between axles is also available in two functions, allowing the possibility to press / lighten either one or both axes simultaneously. Reduces tire and fuel consumption.

2nd axle move assist

Patented and design protected hydraulically operated move assist for steel spring trucks allows weight transfer to drive wheels.

UNDERRUN GUARDS

Side protection plate is combined with the tank protection and our subcontractor's underrun protection boards as options.

SNOW CHAIN BRACKETS

Alternatively, a narrow model attached to the subframe and a wider model mounted on the tank cover.

SUPPORT BUNKS

Alternatives include a short skedbar for crane knee and a longer support bunk to protect the frame during unloading.

GRAPPLE SUPPORT FRAMES

The grapple rests on rubber pads that prevent the grapple from slipping on the support frame. The hinges make the base easy to clean.

Hose boxes

Hoses keep protected and tidy inside the box. Attachment to headboard or together with the grapple support.

Muffler cover

Available easily changable muffle cover made of aluminium.

Mudguards

Fixed, removable and pneumatic mudguards as options. Pneumatic and quick-release mudguards make it easier to add and remove snow chains.

Frame gap sheets

Additional frame gap sheet is available for the mudguards, which protects the chassis from dirt.

Mud flaps

Mudflap brackets can be assembled with, for example, light brackets and boxes as well as step boards.

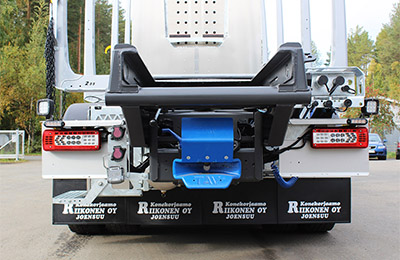

Lights and reflectors

Lots of different models, sizes and mounting options depending on the need and equipment. We install all work lights, headlights, indicator lights, LED lights and reflectors.

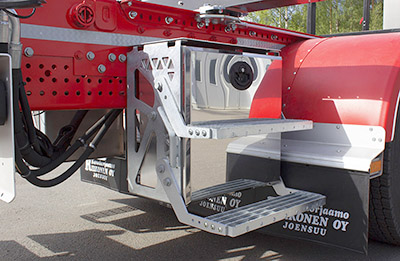

Toolboxes

Different sizes and mounting options according to the need for use. Toolboxes can be installed in combination with, for example, hinged ladders.

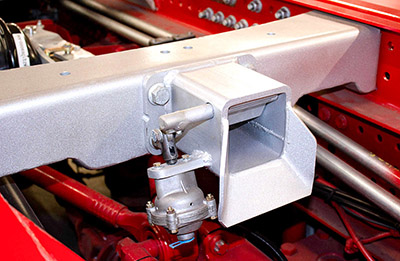

COUPLING EQUIPMENT

TAV and VBG models from our subcontractors are available as options for coupling equipment. Safe, reliable and user-friendly coupling heads and drawbeams fit all frame models.

Ladders

The ladders and step boards can be mounted on the subframe separately or in combination with, for example, a toolbox. Different sizes with fixed and hinged models as options.

Tyre pressure controls

We import, assembly and maintain TIREBOSS™ CTI tyre pressure control systems.

Customization

We produce lots fo unique solutions from special crane brackets to small accessories according to our customers wishes. Ask more about different possibilities.

Rahoitusturva - financing

Konekorjaamo Riikonen Oy is a partner company of Rahoitusturva. Rahoitusturva is a Finnish company specializing in corporate financial services, which offers our business customers flexible payment methods and financing options for products and services. Rahoitusturva services work quickly and effortlessly through online applications.

contact

Ask for more information about our products and services! By submitting the form, you accept the privacy statement.

Antti Pikkarainen

Sales Manager

Superstructures, trailers, cranes, retail

Keijo Riikonen

CEO

Superstructures and trailers, work acceptance, workshop and inspection services

Janne Riihiluoma

Design Engineer

Superstructure product design, brake calculations

Check also these